When it comes to coatings and finishes—acrylic and enamel paints, thinners and solvents, even waterproofing sealants—the Dominican Republic (DR) has counted on Pinturas Tropical to deliver durable products for over three decades. A leading paint and coating producer, Pinturas Tropical operates in Santo Domingo, the capital city and main industrial hub of the Dominican Republic.

When it comes to coatings and finishes—acrylic and enamel paints, thinners and solvents, even waterproofing sealants—the Dominican Republic (DR) has counted on Pinturas Tropical to deliver durable products for over three decades. A leading paint and coating producer, Pinturas Tropical operates in Santo Domingo, the capital city and main industrial hub of the Dominican Republic.

Dosing Difficulties and Batching Blunders

In acrylic paint production, batching is the critical process of mixing various components in precise proportions to achieve a specific formula. Dosing is the accurate measurement and addition of these components during a batching process. Inaccurate dosing leads to bad batches, and that’s exactly what Pinturas Tropical was dealing with.

In acrylic paint production, batching is the critical process of mixing various components in precise proportions to achieve a specific formula. Dosing is the accurate measurement and addition of these components during a batching process. Inaccurate dosing leads to bad batches, and that’s exactly what Pinturas Tropical was dealing with.

The existing PLC-controlled dosing and batching system lacked precision, often resulting in large discrepancies between the requested and delivered amounts of additives. A typical request for 30 pounds of additive could result in anywhere from 20 to 40 pounds, which led to out-of-spec batches and waste.

At Pinturas Tropical, operators had to navigate this inadequate system. To avoid costly errors, they would request just a fraction of the required amount of each additive and add the remainder manually, increasing labor costs and time for the production process, not to mention introducing the possibility of human error.

The existing batching process also lacked automated reporting, another key feature. The absence of historical data, combined with manual operator intervention outside of the automation process, made it impossible to analyze production efficiency and identify areas for improvement.

Superior Solutions for Better Batches

Fortunately, just down the road from Pinturas Tropical is RMS Industrial Tech, a renowned system integrator and certified OptoPartner for automation manufacturer Opto 22. RMS specializes in process control and automation projects, with a strong focus on batch control systems.

Fortunately, just down the road from Pinturas Tropical is RMS Industrial Tech, a renowned system integrator and certified OptoPartner for automation manufacturer Opto 22. RMS specializes in process control and automation projects, with a strong focus on batch control systems.

Operating for the past 23 years under the leadership of Maximo Lugo, RMS implements solutions the DR’s industrial players can count on to enhance efficiency and precision.

Pinturas Tropical contacted Maximo Lugo for a better batching system. Lugo proposed a solution using Opto 22's groov EPIC system. His past experience with Opto 22 products was a factor in his decision, but key features on groov EPIC made it ideal for Pintura Tropical’s batching operation:

Pulsing for pumping precision:

Pulsing for pumping precision:

The new system was designed to address precision issues head-on, using Time Proportional Output (TPO) to control dosing valves. TPO is a form of Pulse Width Modulation (PWM) that works by controlling the duration that a dosing valve is open and using fixed timing cycles to precisely control flow rate from the dosing pump.

TPO was enabled using groov EPIC’s GRV-ODCSRC-24 discrete DC output module and Opto 22's PAC Control flowchart-based programming software.

Modbus for measurement:

Lugo made use of the free Modbus/TCP integration kit provided with PAC Control to communicate in real time to custom-built weight scales. Each scale had a Modbus/TCP enabled transmitter outfitted with 4 load cells. Using high-speed Ethernet communication provided real-time feedback on the amount of additives delivered.

groov View for visualizations:

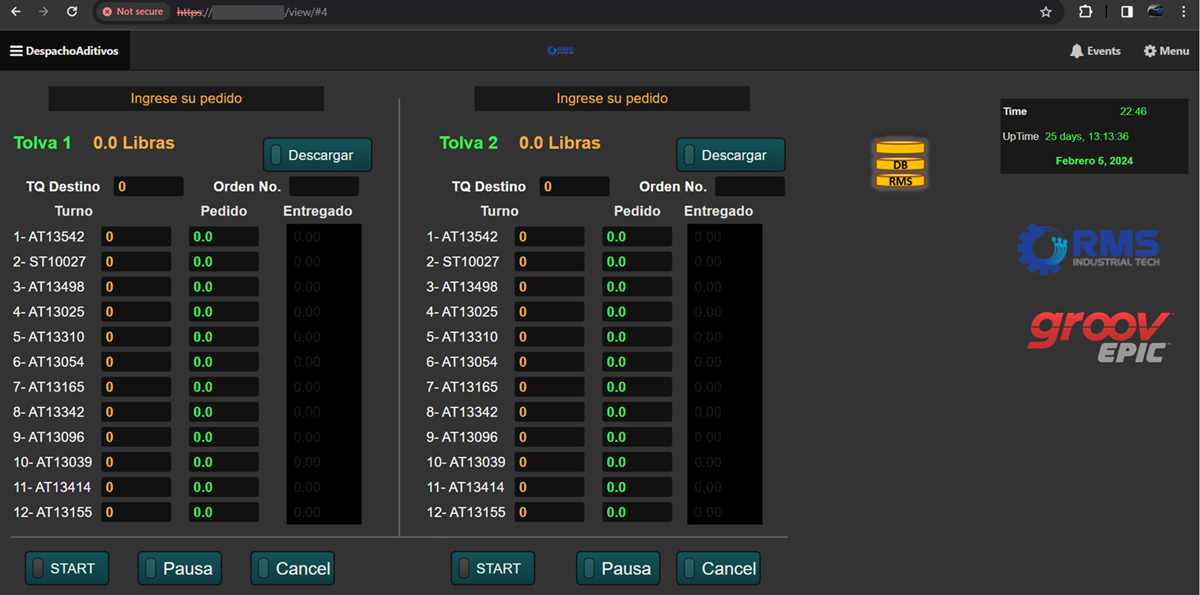

Each groov EPIC comes with a web-based visualization software called groov View, which allows any user on the network with the appropriate credentials to see current and historical status of the system.

Lugo also utilized groov View as a way for operators to enter batch parameters and signal the system to start or stop batching operations.

Node-RED for record keeping:

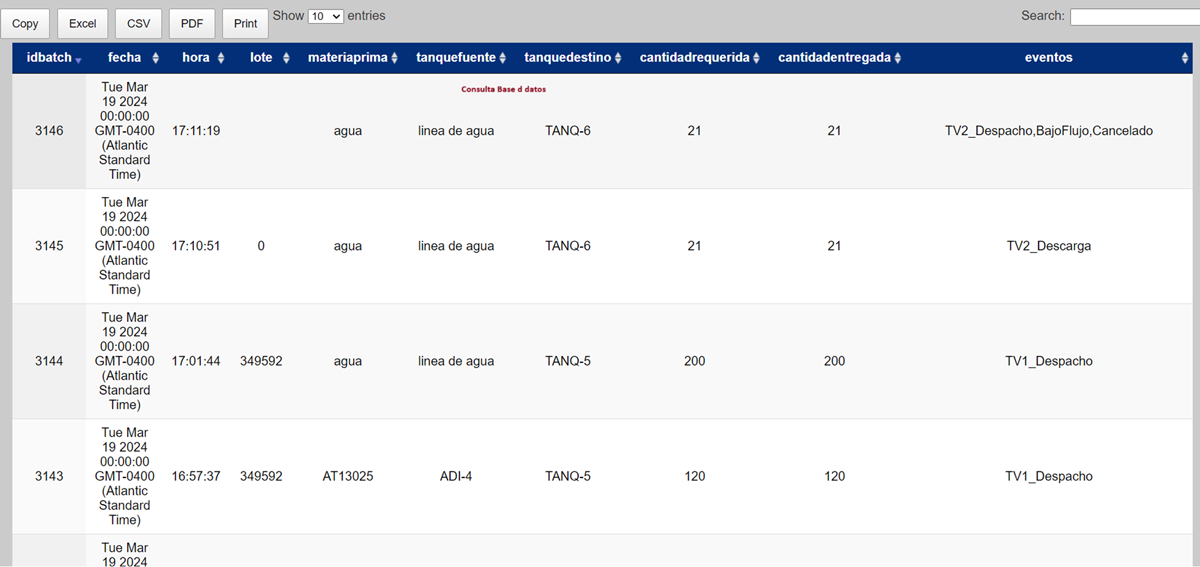

Since each groov EPIC also comes preloaded with Node-RED, a flowchart-based programming environment for IIoT applications, RMS made use of the open-source platform to write batch data to a PostgreSQL® database. Lugo recalls, “At the end of each batch, a PAC Control variable is toggled true, which signals Node-RED to read a string table that contains all the batch information: batch number, requested amounts, delivered amounts, target time, date/time, etc. From there, we use a Node-RED PostgreSQL node to move those values into a database."

RMS’s approach ensured the exact amount of additives being injected into the paint batches, eliminating waste and maintaining the stringent quality standards of Pinturas Tropical. Better visualization and record keeping meant tighter control over their system and better ability to analyze production and any issues that may arise.

Batching page in groov View

PostgreSQL database records using Node-RED