Paloma Irrigation and Drainage District Reduces Downtime and Pump Repair Costs

groov devices provide flexibility and scalability for SCADA expansion

The Paloma Irrigation and Drainage District (PIDD), spanning 30,000 acres in Gila Bend, Arizona, underpins the region's agricultural production. It supplies water to diverse crops, including alfalfa and cotton, and supports dairy operations, contributing to the area's varied agricultural output. Additionally, the district provides domestic water services to nearly 100 homes.

District Manager Robert VanHofwegen heads the water management network, ensuring effective delivery through a combined system utilizing Gila Bend Canal and groundwater sources. This approach fuels both agricultural growth and the prosperity of the local community.

More than just irrigation, the PIDD safeguards the environment and upholds the community's water rights. Their commitment to sustainable water practices aligns with Gila Bend's agricultural vision, ensuring long-term prosperity for both flourishing fields and surrounding homes. In this resource-scarce landscape, the district plays a crucial role in sustaining the thriving agricultural hub.

Gila Bend main canal at Gillespie Dam

Challenges

But in 2019, the PIDD faced several pressing challenges, culminating in the need for a strategic shift towards an Industrial Internet of Things (IIoT) approach. Here's a closer look at the key issues:

Inefficient Manual Operations

- Time-consuming & laborious: Technicians relied on manual controls and frequent site visits for monitoring and adjustments, reducing efficiency and introducing delays.

- High maintenance costs: Frequent pump failures due to lack of continuous monitoring resulted in annual maintenance expenses of $300,000 - $400,000, creating a financial burden for the district.

- Reactive management: The district's inability to proactively respond to changes in water demand or system failures hindered optimization and problem prevention.

Limited Visibility and Control

- No real-time monitoring: Absence of real-time data left the district unaware of issues that were impacting water delivery.

- No remote control: Inability to remotely control systems limited flexibility and timely responses to issues, potentially leading to supply interruptions.

These challenges highlighted the critical need for a more modern, cost-effective, and data-driven approach to water management, paving the way for the districts's exploration of IIoT solutions.

Paloma Irrigation lift station

First Try: Raspberry Pi

In a bid to address the challenges of outdated systems and modernize operations, PIDD District Manager VanHofwegen explored an unconventional solution: Raspberry Pi®. These low-cost, versatile devices offered a potential entry point into leveraging IIoT technology for improved water management. Their affordability allowed VanHofwegen to experiment with IIoT applications without significant upfront investment.

Raspberry Why?

Leveraging Raspberry Pi proved successful, laying the groundwork for the district's IIoT strategy. PIDD also adopted Node-RED®, a user-friendly flow-based programming tool, and FlowFuse™, a platform for remote device management, to more easily integrate hardware with online services. Node-RED’s visual programming eliminated the need for extensive coding, enabling the development of sophisticated irrigation management solutions at a low price. Remote management capabilities improved, significantly reducing reliance on manual checks.

Raspberry Bye!

Despite initial success, Raspberry Pi solutions presented new challenges. While cost-effective and adaptable, they displayed limitations in reliability and durability. Sensitive to environmental fluctuations common in industrial settings, they also required substantial customization, delaying the expansion of digital transformation projects.

These vulnerabilities highlighted the inefficiencies in deploying consumer-grade technology in a demanding industrial context. PIDD needed a solution that was not only robust and reliable, but also streamlined for quick deployment. Their experience led the district to seek an industrial-grade alternative better suited to their needs.

The Move to groov

Faced with limitations of Raspberry Pi, Paloma Irrigation and Drainage District sought a robust, industrial-grade IIoT platform. This search led VanHofwegen to a solution that transformed their operations: groov devices from industrial automation manufacturer Opto 22.

This search led VanHofwegen to a solution that transformed their operations: groov devices from industrial automation manufacturer Opto 22.

“I don’t remember exactly how I found it, but what turned me on was that it was ready out of the box to be integrated with our existing Node-RED-based strategy. Beyond that, groov devices fit well into our future plans to migrate to Ignition® SCADA. Everything about it seemed designed around ease of use and reliability, which was exactly what we needed,” VanHofwegen recalls.

Reasons for Choosing Opto 22 Products

- Industrial durability & reliability: With a proven track record in harsh environments—unlike the more sensitive Raspberry Pi—

groov products reduce maintenance and ensure operational stability.

groov products reduce maintenance and ensure operational stability.

- Affordability: groov RIO units at roughly $1,000 each are significantly cheaper than existing industrial-grade pump monitoring/control solutions, making them a more cost-effective option.

- Modular design: groov EPIC's modular design allows for customization of I/O per pumping station, with the flexibility to expand as needed.

In selecting

groov products, PIDD embarked on a new phase of its modernization journey, now armed with technology that aligned with their goals for efficiency, reliability, and future scalability. They were poised to transform their water management practices and set a potential new standard for precision and control.

The groov Learning Journey

In the initial exploratory phase, VanHofwegen actively engaged with Opto 22's online training resources, especially YouTube® tutorials and demonstrations. These materials comprehensively cover groov product functionalities and proved crucial for understanding MQTT integration, which was vital for the district's IIoT roadmap.

The detailed walk-throughs and use-case scenarios in Opto 22's videos offered practical insights into the real-world capabilities of groov products, confirming their alignment with the district's needs. This, combined with the district's existing MQTT expertise and HiveMQ® broker usage, underscored the potential for seamless integration and robust data communication, ultimately solidifying their decision.

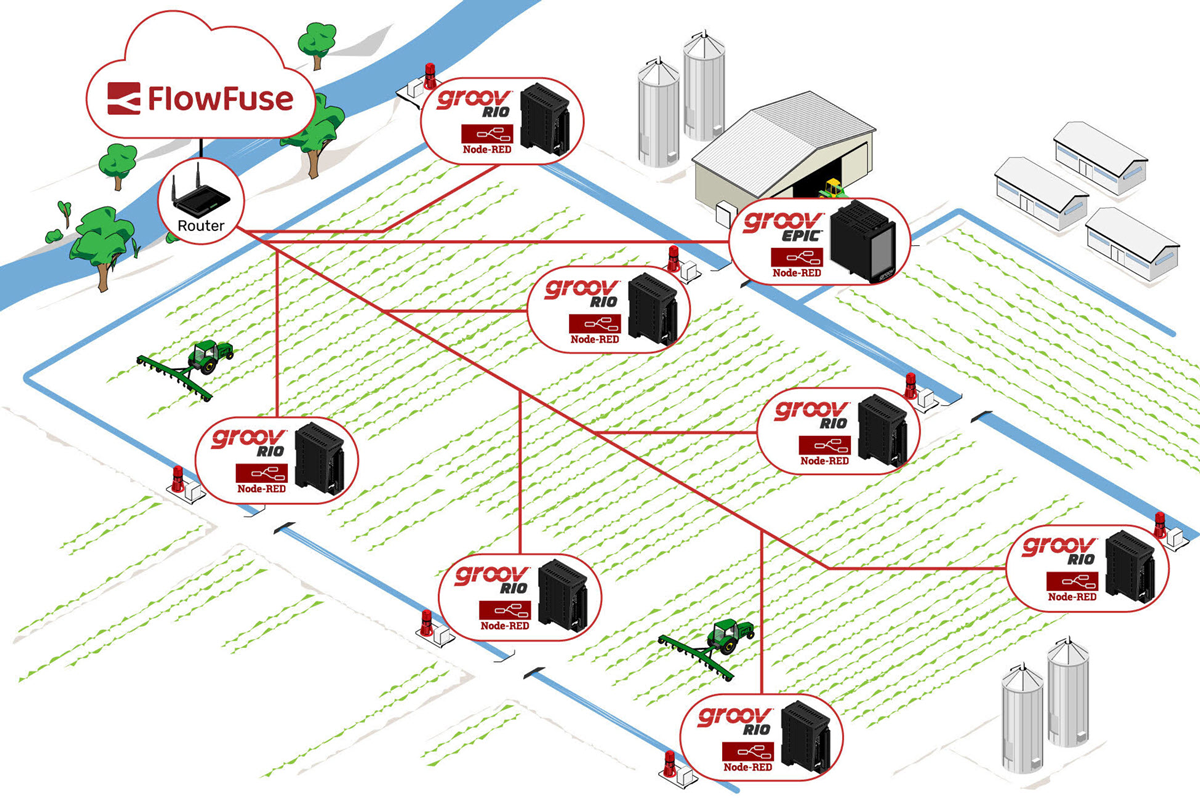

Illustration of PIDD site technology