Case Study: FCI Watermakers

OEM improves large-scale seawater reverse osmosis system design with groov EPIC

Question: What do a yacht owner, an island resort, and a Las Vegas chef have in common?

Answer: They all need a reliable source of good fresh water—and they all count on FCI Watermakers to provide it.

The Company

From small yachts to offshore oil platforms, from fish hatcheries to resort hotels, customers of FCI Watermakers know their freshwater need will be satisfied, whether it’s for just 200 gallons or for 260,000 gallons per day (GPD).

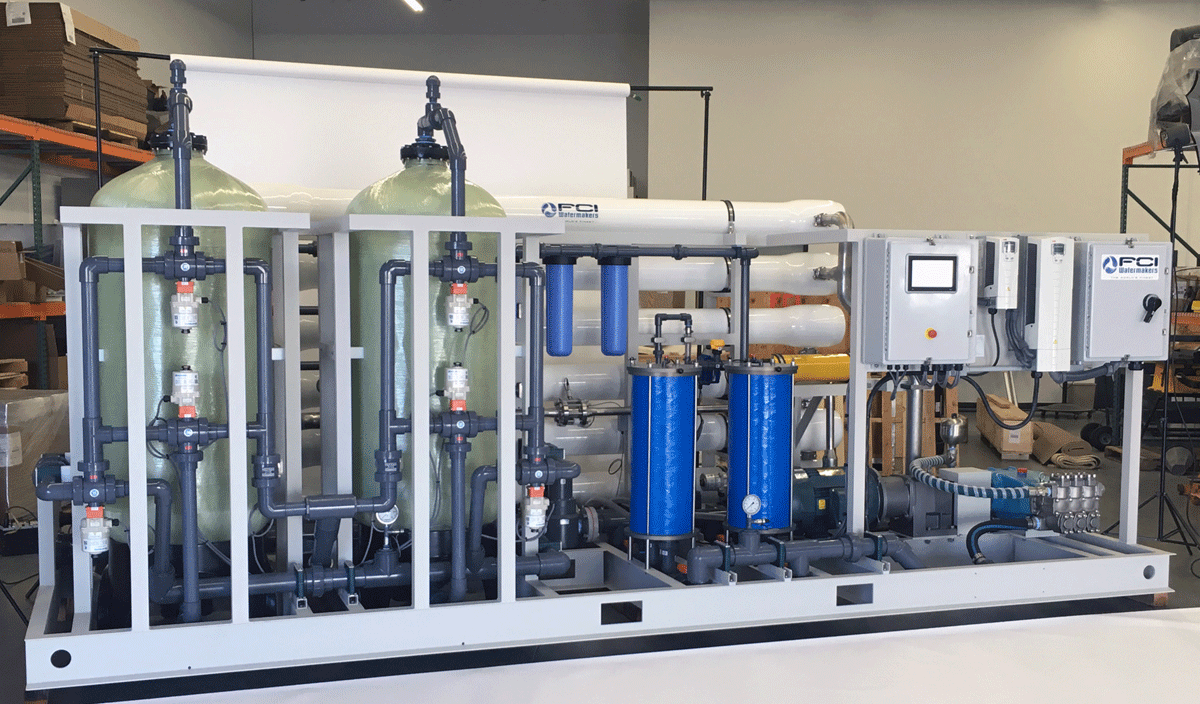

The West Valley, Utah-based company has been building freshwater systems since 1992. Most are skid-mounted systems that primarily convert salt water to fresh water via reverse osmosis, but several other technologies are also used depending on the customer’s needs.

Starting with two product lines in 1992, the company has expanded to offer a wide range of systems, large and small, for customers worldwide.

“If it floats or is surrounded by water,” says Scott McGuire, President of FCI Watermakers and founder of the company, “that’s where we are.”

McGuire got his start in the field in the 1980s at the age of 18, working for a company that designed reverse osmosis systems for pleasure yachts. He soon found he had his own ideas about how those systems should be engineered and manufactured. To put them into practice, he started Filtration Concepts, Inc. (FCI).

High-quality Systems

The quality and longevity of FCI’s systems set them apart from competitors in the field. Their systems are designed to be easy to use and service, with options for completely automated operation or manual controls.

The quality and longevity of FCI’s systems set them apart from competitors in the field. Their systems are designed to be easy to use and service, with options for completely automated operation or manual controls.

An open-frame design for most of their products makes it much easier for customers to service their systems, as components are placed for easy access and maintenance.

FCI products are manufactured to high standards and typically built for marine environments; they are ship certified and marine grade. The HMI panel FCI uses is the only one in their field that is marine certified and uses resistive touch technology, so customers can use it while wearing gloves.

The result of this attention to quality and serviceability is less downtime, more fresh water, and high customer satisfaction.

While yacht systems are the company’s bread and butter, McGuire finds the bigger, more unique systems more challenging and therefore more interesting from an engineering standpoint.

The Chef

For example, the pastry chef at a hotel in Las Vegas was frustrated that his baked goods didn’t come out the way he expected, and he finally traced the problem to the local water.

The chef was used to New York City water, which is filtered through granite and has an excellent reputation for taste. It has a specific pH and total dissolved solids (TDS) profile, and those qualities in the water affect the performance and taste of baked goods. TDS include inorganic salts (calcium, magnesium, potassium, sodium, bicarbonates, chlorides, and sulfates) and some small amounts of organic matter.

FCI designed a custom system that filters and treats the local water to bring it up to the chef’s standards.

The Resort

One of FCI’s larger customers is a resort in the South Pacific. Surrounded by seawater, the island has little fresh water. When their old system of converting seawater to fresh began to fail, they looked to FCI for a replacement.

Goals were not only to have a sufficient volume of water, but also to convert it using as little energy as possible. Diesel-run generators provide all the power on the island, and electricity is very expensive.

FCI solved both problems by providing a custom-designed skid-mounted freshwater conversion system for the resort. Not only does it provide plenty of fresh water for all the resort’s needs, but it also massively reduces energy costs by running on 30 hp rather than the previous 100 hp. FCI can recover up to 40% of energy by using pressure exchanger technology, which captures energy in the brine stream and then feeds it back into the system.

An FCI Watermakers custom water filtration system

The Challenge: Controlling Custom Systems

As an original equipment manufacturer (OEM), FCI builds their own controls for their products. When custom orders and larger systems became a bigger part of their business, McGuire began looking around for more flexible automation tools.

“Three or four years ago, ladder logic was the best fit for our V4 HMI/PLC,” says McGuire, but he began looking for a control system that would be easier to use and to scale. The V4 PLC was limited to a finite amount of I/O, which was fine for smaller systems but too limiting for larger ones. Instead, McGuire wanted to have everything they needed built into one unit.