Retort furnace

A rotating cylindrical retort conveys parts from one end to the other by slowly tumbling parts forward across a series of internal vanes. Internal temperature is maintained by Eurotherm 3204 PID controllers, and a two-position selector allows the operator to drive the furnace continuously in one direction or to select alternating back-and-forth motion when longer dwell times are needed.

The period of the alternating cycle is controlled by a dual-setpoint timer, and the rate of rotation is controlled by an Allen-Bradley PowerFlex 525 variable frequency drive (VFD) and a 1 HP motor through a 900:1 gear reducer. Operators manually set the output frequency of the drive via its integrated control panel.

Quench tank

Parts fall from the end of the furnace through a chute into a 7,000-gallon tank where they are cooled in either water or oil. The quenchant is circulated constantly by a fixed-speed pump driven by a 30 HP 230V 3-phase AC motor.

Conveyor

Treated parts are removed from the quench tank by a conveyor belt driven by a 2.5 HP 230V 3-phase AC motor.

Control platform evaluation

Given the scope of its controls upgrade—including computerized weighing, burner control, and drive control—AMP knew it would require a custom solution. After receiving quotes from several industry system integrators, it became clear to Pinkos that AMP had two options: “Either we pay someone $60K and give them the keys to the car, or we consider a homegrown solution.”

Most of the companies that Pinkos contacted wanted to completely rebuild the feeder system electrical panels, including custom programming for new PLCs and accompanying HMIs, leaving AMP with no access to the source code unless they also paid for the required design software licenses. AMP wondered whether it could take on the job itself, potentially reducing costs and giving it the option of retaining full ownership of its control logic.

“For a business like ours with less than 25 employees,” explains Pinkos, “developing a solution in-house is inherently more attractive than paying an outside company, since it allows us complete control over the product and we can modify, adapt, or expand it as our needs change. Our process is something that can be sketched out on a whiteboard, and we believed the solution should be simple to implement and understand.”

AMP began researching what a homegrown solution would require. It identified Opto 22 as a potential solution vendor while exploring a feeder system I/O panel dating back to 1993. “Opto 22 I/O modules were some of the few parts still working,” according to Pinkos. “We got a quote for a groov EPIC system and were very impressed with the value and versatility offered.”

New electrical panel layout with groov EPIC and accompanying groov View HMI

With EPIC as a potential foundation for its new control system, AMP began mapping out a path to the goals it had identified using the content available through Opto 22’s developer forum, free training videos, and support channels. Pinkos, a chemical engineer by education, began learning Opto 22’s free PAC Control programming software with guidance from sales and support staff.

The experience gave AMP the direction it needed, as Pinkos relates. “I could see the pieces coming together. Opto 22 does an amazing job of teaching people who don't have a background in programming. When I realized I could do data logging with groov EPIC, that checked another box for me. Once we found a way for our lot tracking database to use REST calls to extract data from the groov EPIC, then we had a complete solution. EPIC made it possible to create a homegrown system.”

System upgrade

AMP began developing its first groov EPIC system with a phased plan for upgrading each of its seven furnace lines. A month later, however, AMP suffered a critical PLC failure on one of its lines and decided to put an early version of the new system into service.

Built on the

groov EPIC processor (

GRV-EPIC-PR1), the first system incorporated the following I/O modules, each with channel-to-channel isolation, which allowed AMP to establish a basic control system:

- GRV-CSERI-4: 4-channel serial communication module

- GRV-OVMAILP-8: 8-channel V/mA analog output module with chassis-supplied loop power

- GRV-ODCIS-12: 12-channel simple discrete DC output module

- GRV-ITMI-8: 8-channel thermocouple/mV analog input module

The feeder system scale was monitored through one of the system’s serial inputs, with both vibratory stages controlled through 0–10 VDC outputs.

The retort furnace controls were integrated into the control program using one serial input channel to measure the rotational speed of the furnace, one analog output for setpoint control to the VFD, one discrete DC output to the VFD to control the direction of rotation, and four temperature readings of the furnace body and internal atmosphere.

The conveyor was integrated into the control program using an additional serial input to monitor the belt speed.

Finally, AMP’s groov EPIC was connected to the company network, completing a basic design that laid the foundation for continuing enhancements.

Because groov EPIC uses a quad-core ARM processor capable of running multiple applications in parallel and includes additional software applications, control logic was just the beginning of AMP’s modernization program.

Operator interface

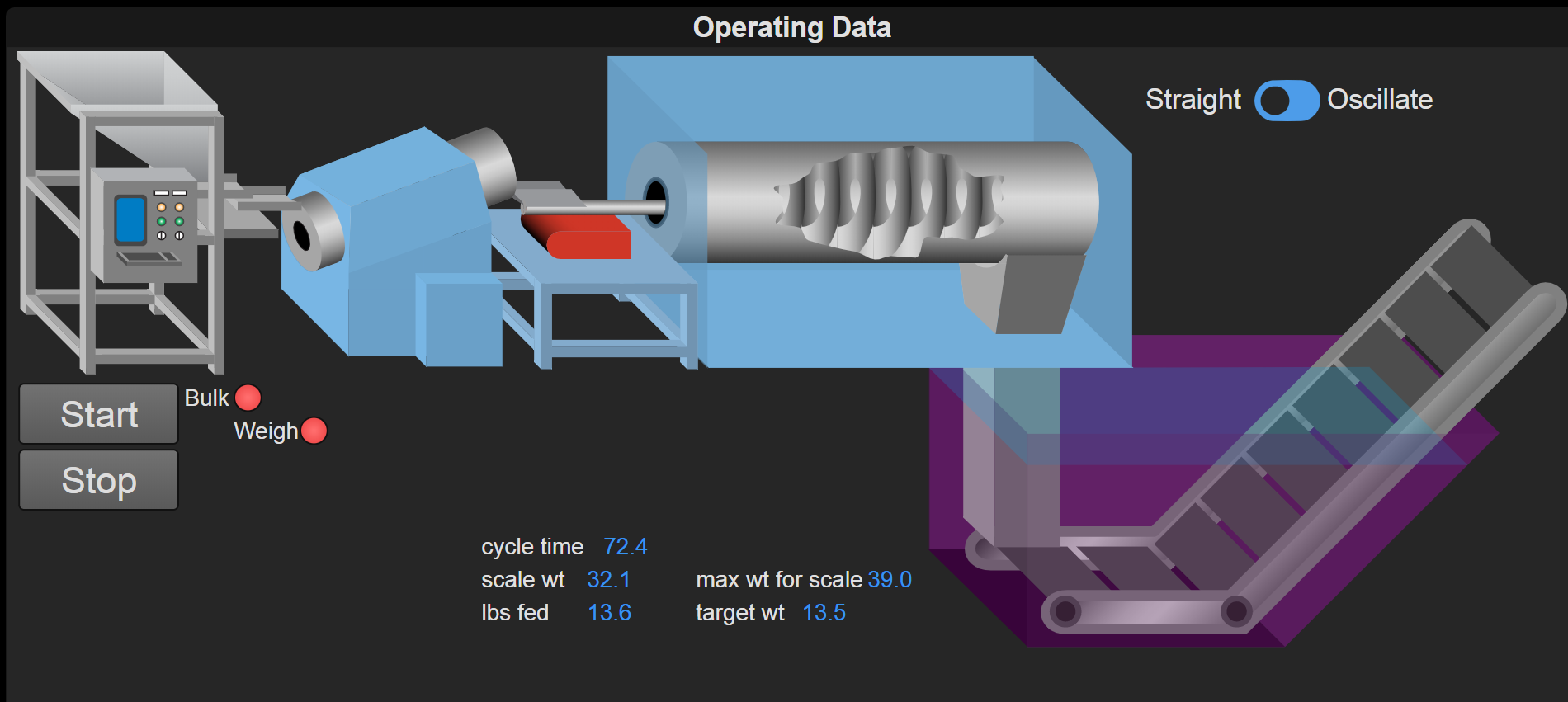

One of the software applications included with groov EPIC is groov View, an embedded visualization server for creating on-board, external, mobile, and desktop HMI displays. Along with duplicating the functions of the previous PC-based feeder HMI in groov View, AMP took the opportunity to integrate other control elements and create a unified operator interface.

Furnace temperature, retort speed (which corresponds to dwell time), and quench tank temperature were added to the existing feed system readings, while the manual furnace timer and rotational direction selector components were replaced with HMI control gadgets. The result was a logically arranged operator interface “that anyone could understand,” according to Pinkos.

groov View HMI—operator controls and process read-outs