The Challenge of the IIoT

Getting data from the edge of the network—from the sensors and actuators in factories, buildings, and remote sites—to the software and people who need to use it is hard. It involves:

Getting data from the edge of the network—from the sensors and actuators in factories, buildings, and remote sites—to the software and people who need to use it is hard. It involves:

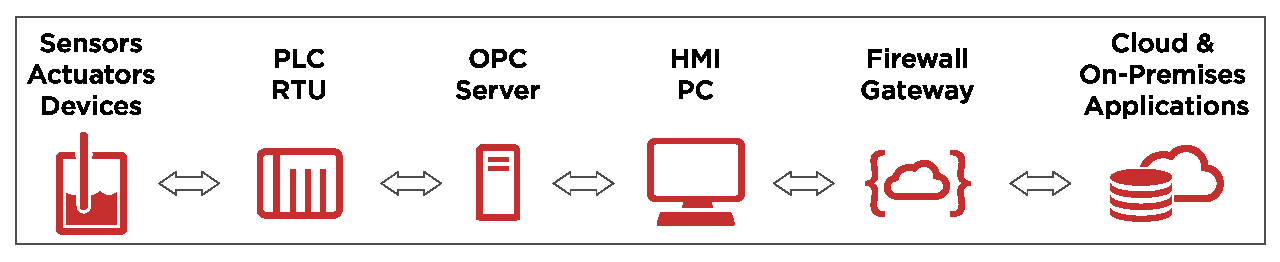

Field devices understand electrical signals, but computers and mobile devices don't. Most control systems are proprietary or specific to automation—EtherNet/IP, Modbus, Profibus, serial, OPC. But computers and mobile devices use standard Ethernet or WiFi networks and open protocols like TCP/IP, HTTP/HTTPS, JSON.

It takes a chain of middleware to translate data between these systems and move it where you want it. Hardware, drivers, parsers, and custom software are costly to purchase, install, and maintain, and every link in the chain opens security concerns.

For example, here's a typical IIoT setup:

CHALLENGE:

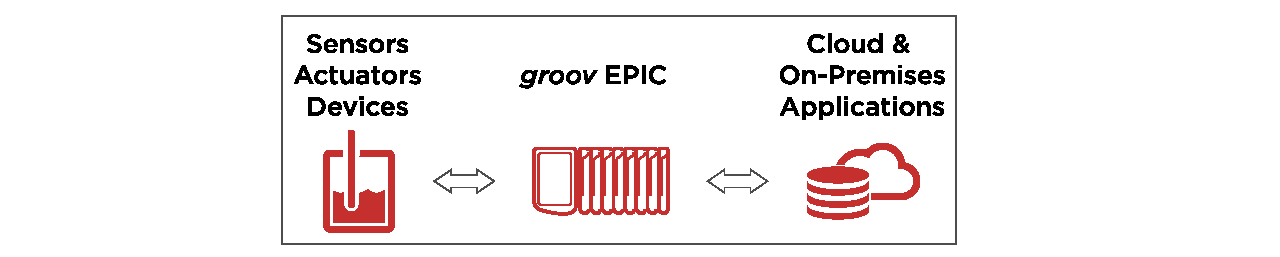

We need a simpler way. We need an EPIC improvement—an Edge Programmable Industrial Controller. Opto 22's groov EPIC eliminates middleware and shrinks the steps to get the data we need:

SOLUTION:

How does groov EPIC solve the challenge?

An edge programmable industrial controller, groov EPIC is much more than a PLC or a PAC. We designed it from the ground up as both a reliable real-time industrial controller and a processor to collect, process, display, and exchange data.

groov EPIC talks directly to field devices, other control systems, databases, cloud services, and a lot more. EPIC helps solve the challenges of complexity, security, and cost.

See how groov EPIC fits in your system architecture.

“Some engine and pump companies are hungry for automation. Some have systems, but they don’t communicate with each other. EPIC makes them talk.”

- Dan Arbeau, CEO, netDNA (Oil & Gas)