The Customer

Azcal Management farms 8,700 acres in Kings County, California, in the heart of the San Joaquin Valley. They farm a diverse range of crops including pistachios, wine grapes, alfalfa, and row crops like onions, garlic, and tomatoes. Pioneers in precision agriculture technology, Azcal focuses on increasing production, on efficiency, and on improving crop quality.

In drought-prone California, farmers walk a fine line on water use. Water costs, government regulations, and concern for future water availability all mean they must start focusing much more on providing just enough water for crops, not too much or too little.

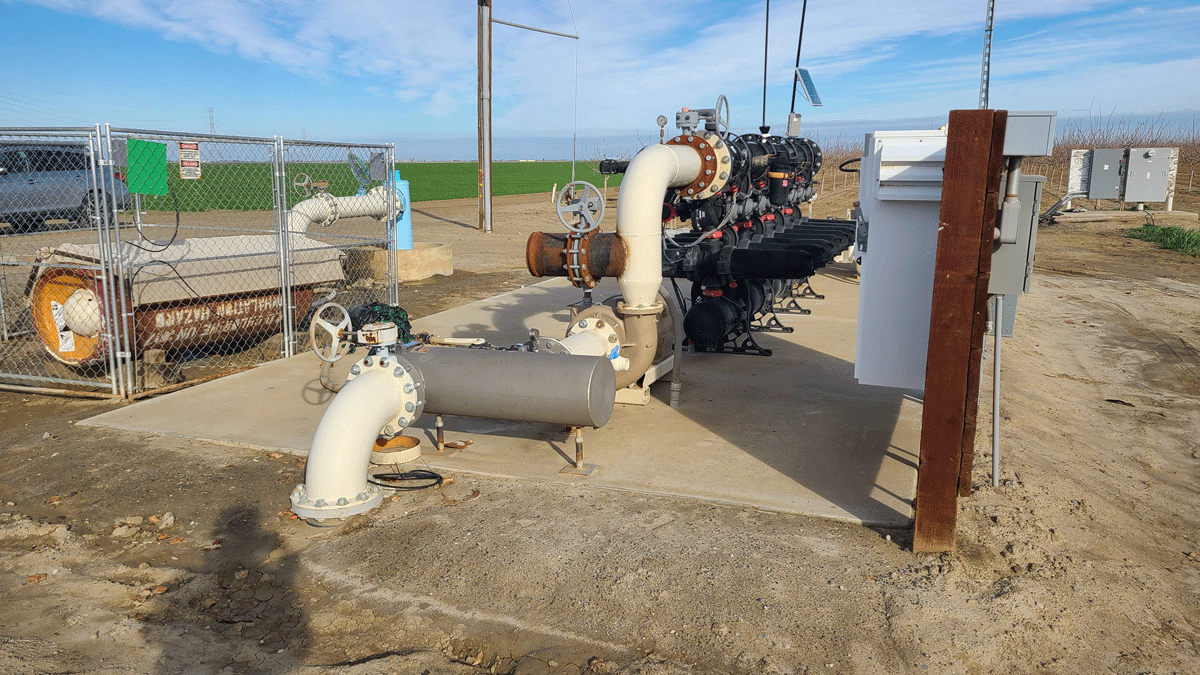

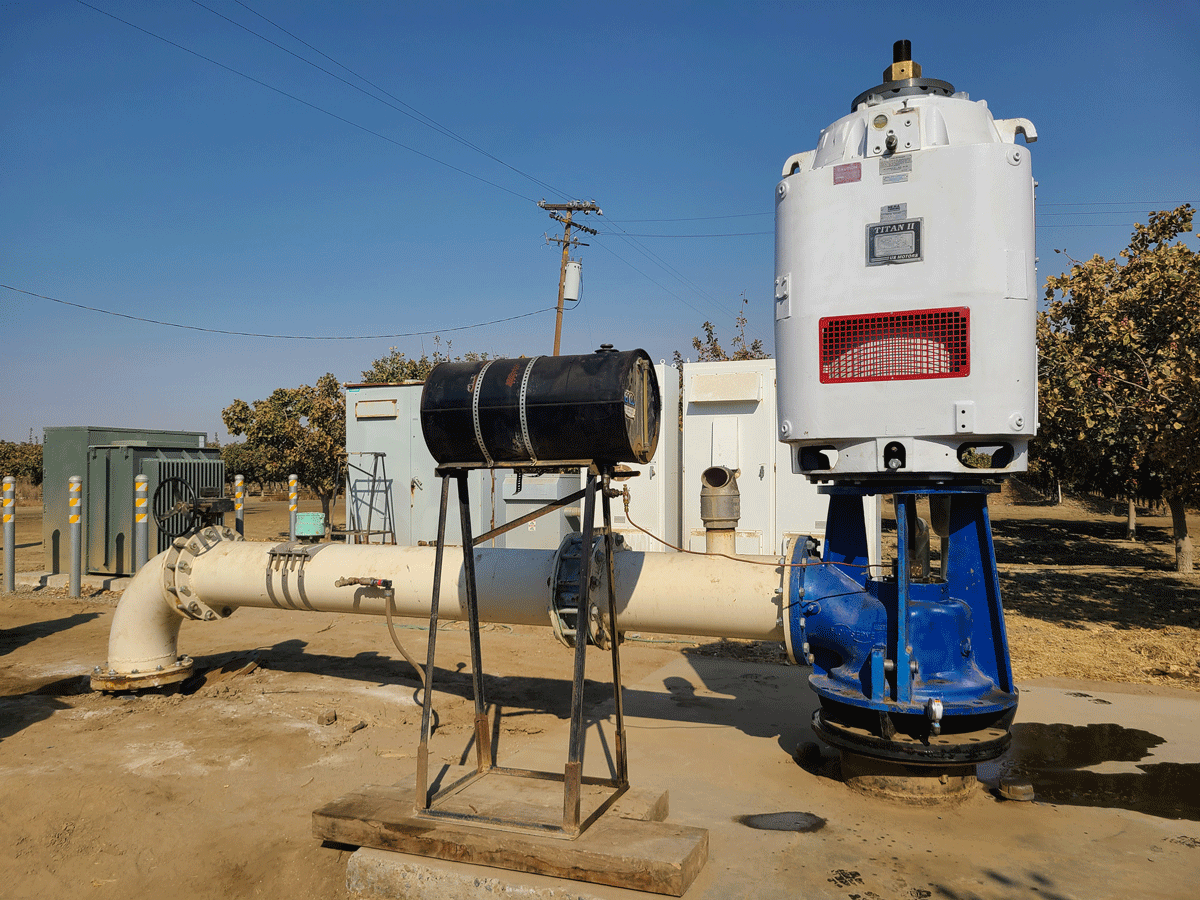

One of the Azcal ranches has 12 deep-well pumps, all with VFDs (variable frequency drives), feeding a single mainline serving a 4,000 acre ranch just south of Lemoore, California. Monitoring and controlling these pumps used to be a full-time job for farm managers Jake Sheely and Marty Rhoads. It took six to seven hours throughout each day to drive around the ranch and make the needed micro adjustments to pumping and irrigation systems.

All Azcal wells and irrigation filter stations are equipped with VFDs and flow meters.

Their monitoring was vital, ensuring that system pressures and flows were within range and that pumps were operating efficiently. With four or five well pumps running at the same time, Jake and Marty had to be extremely diligent to avoid both low and high pressure events and often had to switch wells based on farming needs.

The wells must be kept in operation but not overdrawn. A drop in the flow rate would mean the well was overdrawn, and if air was sucked into the pump, the well could require thousands of dollars to repair. In addition, like many growers, they also suffered from power failures and incoming voltage spikes. It could be several hours before they realized a pump was no longer running or had burned up.

The time involved in manual monitoring and control was just too much. Azcal looked for a simple way to automate their water management and track pumping events for monthly water accounting.

Azcal well pumps all feed the same mainline pipe, leading to complex pressure management requirements.

Azcal interviewed several Ag Tech providers about their need for remote pump monitoring and control. They tried proprietary tools designed for pump control, but although these tools worked for one pump and 40 acres, none of them could integrate everything at scale. And there was limited support for remote control or sophisticated PID loop control.

Discouraged, Azcal was dubious when Farm Data Systems (FDS) in Madera, California, approached them with some new technology. However, FDS owner and president John Williamson had worked on projects for them with a previous company, so they were willing to listen.

“No one has been able to deliver what we needed,” said Jake.

The System Integrator

“Not that many system integrators serve the Ag market,” explains John. “They are focused on post-harvest—pack houses—not really in the field.”

“Not that many system integrators serve the Ag market,” explains John. “They are focused on post-harvest—pack houses—not really in the field.”

As John notes, agricultural customers are trying to solve fairly simple problems, but there are so many difficulties that it becomes complex. Assets are spread out over wide distances. You can’t run Ethernet wiring; the system has to be wireless. And cost is a huge factor, as farms don't usually have big budgets.

But the engineers at FDS have spent the last 20 years figuring out how to make technology in the field both relevant and cost-effective to growers. In the early years they used their own technology for monitoring, but customers began asking for more and more features. So FDS standardized on Opto 22 hardware and Ignition software from Inductive Automation®, bringing agriculture into the internet of things.

“Five years from now I don’t know how anyone will be able to farm efficiently without this IoT technology,” says John.

Using the Opto 22 hardware and Ignition software, FDS has developed an end-to-end field monitoring and automation solution for crop irrigation management.

- Opto 22 groov EPIC controllers and groov RIO modules connect to sensors and equipment in the field to gather data and automate control.

- FDS’ Water Informatics platform, an Ignition project hosted on FDS’ private cloud, provides the control and data that farmers need in a way that they understand and can easily use. Each customer has a private view based on their login that shows just the assets and information for their ranch.

By avoiding expensive custom hardware that can be time consuming to build and maintain, FDS can keep prices affordable while also limiting downtime if something needs to be replaced or upgraded. With off-the-shelf controllers, sensors already widely used in many other industries, and their own easy-to-use software, FDS’ systems are very affordable for farmers.

Not only has the company significantly improved irrigation management at over 500 farms covering more than 50 crops, they also farm their own 200-acre technology lab to test system improvements.

Azcal filter stations typically serve multiple crops in fields of various sizes.

The Solution

What Azcal needed was a controller at each well pump, fully integrated with their existing VFDs, that would allow them to remotely start and stop pumps as well as make micro-adjustments to either the speed or the pressure setpoints. They also needed reliable monitoring of flow meters and incoming voltage.

FDS met Azcal’s needs with an integrated, modular architecture that can be easily adapted to meet the unique requirements of each customer.

The Hardware

Farm Data Systems began using Opto 22 controllers and I/O several years ago. They had used Allen-Bradley® products for pump control, but the systems were too expensive for most farms.

When they discovered that new IoT products from Opto 22 could do the same things more efficiently, John says, “Opto opened the door into Ag for us.”

Initially they chose the Ethernet-based, rack-mounted SNAP PAC R-series controllers and I/O for field installations. When Opto 22 released groov EPIC and groov RIO, however, they saw an opportunity to reduce costs further.