Mechanical Design Process

Turning the concept and processing requirements into a full-scale functional system is where Guy Chetrit came in.

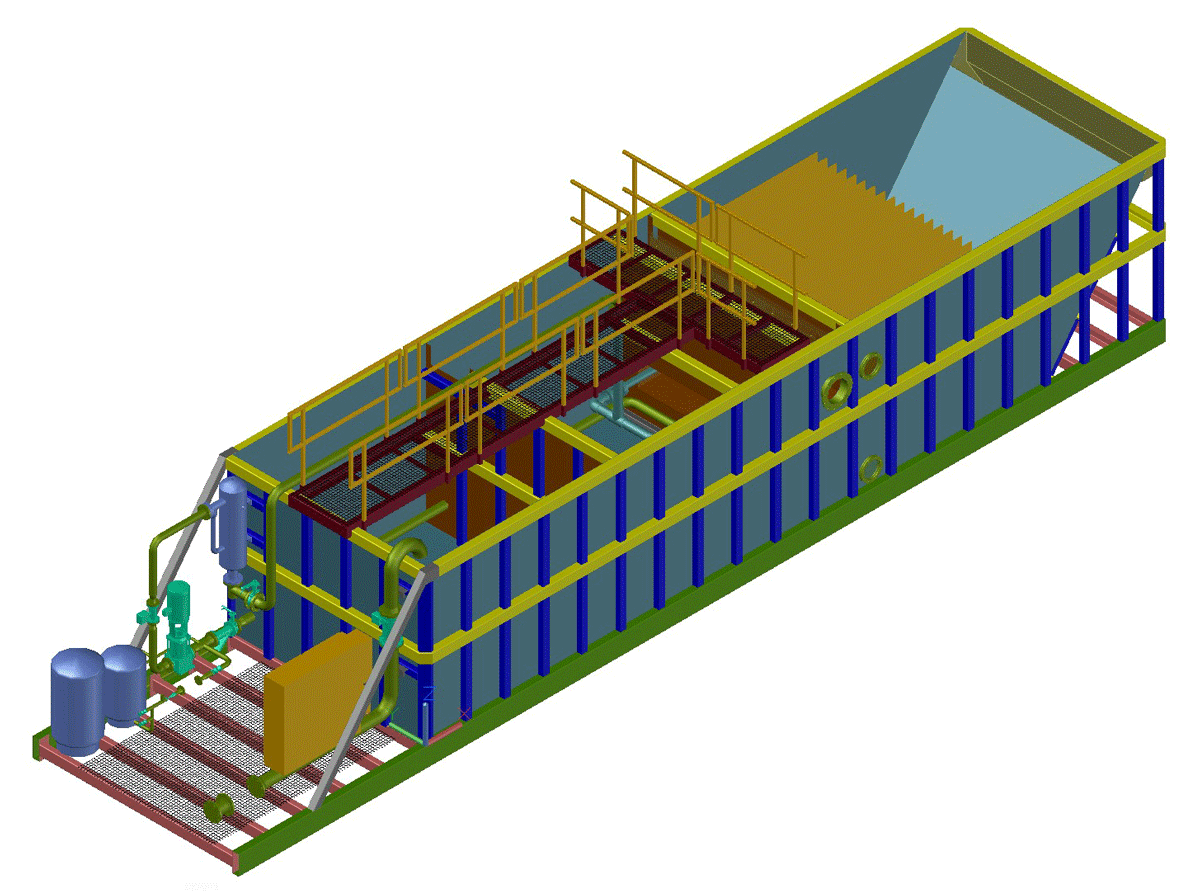

The processing skid was first modeled in 3D CAD to visualize the design progression in detail. Process control parameters include flowrates, mixing effectiveness, contact times, hydraulic loading, solids loading, skimming rate, and more. Structural considerations were closely modeled as well.

The system was designed for outdoor placement in remote locations and is self-sufficient. Only an external power source is required, either a generator or a power grid connection, if available. Cellular telemetry provides remote connectivity wherever cellular service is available. Electrical components are rated NEMA 4x, and all components are corrosion resistant. Not only wetted components, but the entire skid—including its structural members—is constructed of stainless steel.

Schematic of a one million gallons per day (1 MGD) HFT algae harvester

To reduce material costs and use raw materials efficiently, the team produced creative solutions that decrease waste. They minimized the use of plastics for sustainability and environmental reasons, and developed custom structural profiles to meet size and strength requirements.

Individual steel components were optimized for strength. They used finite element analysis (FEA) to model and evaluate the completed skid under all loading conditions, from analysis for transportation and hoisting of the empty system, to stationary hydrostatic loading when all compartments are filled with water.

Fabrication as well as field deployment were an ongoing consideration. Detailed and certified fabrication drawings were released incrementally to meet deadlines. Guy, David, and the fabrication facility closely collaborated on design progression, with shop visits for inspections and testing.

Control System

To control the process, collect and distribute data, and provide a user interface for operators and observers, the algae harvester employs a groov EPIC® System from Opto 22. Guy Chetrit has used Opto 22 products for some years and has been to Opto 22 factory training twice, most recently in late 2019, when he trained on the groov EPIC system.

He noted the ways in which the EPIC differs from other industrial controllers and chose EPIC for the harvester system based on the features he needed for the project:

● Real-time control

● Easy-to-use tools for programming and HMI

● USB flash drive capability for logging data

● Built-in Modbus communications via a USB-to-serial adapter

● VPN client

● Additional cloud communication capabilities for future expansion

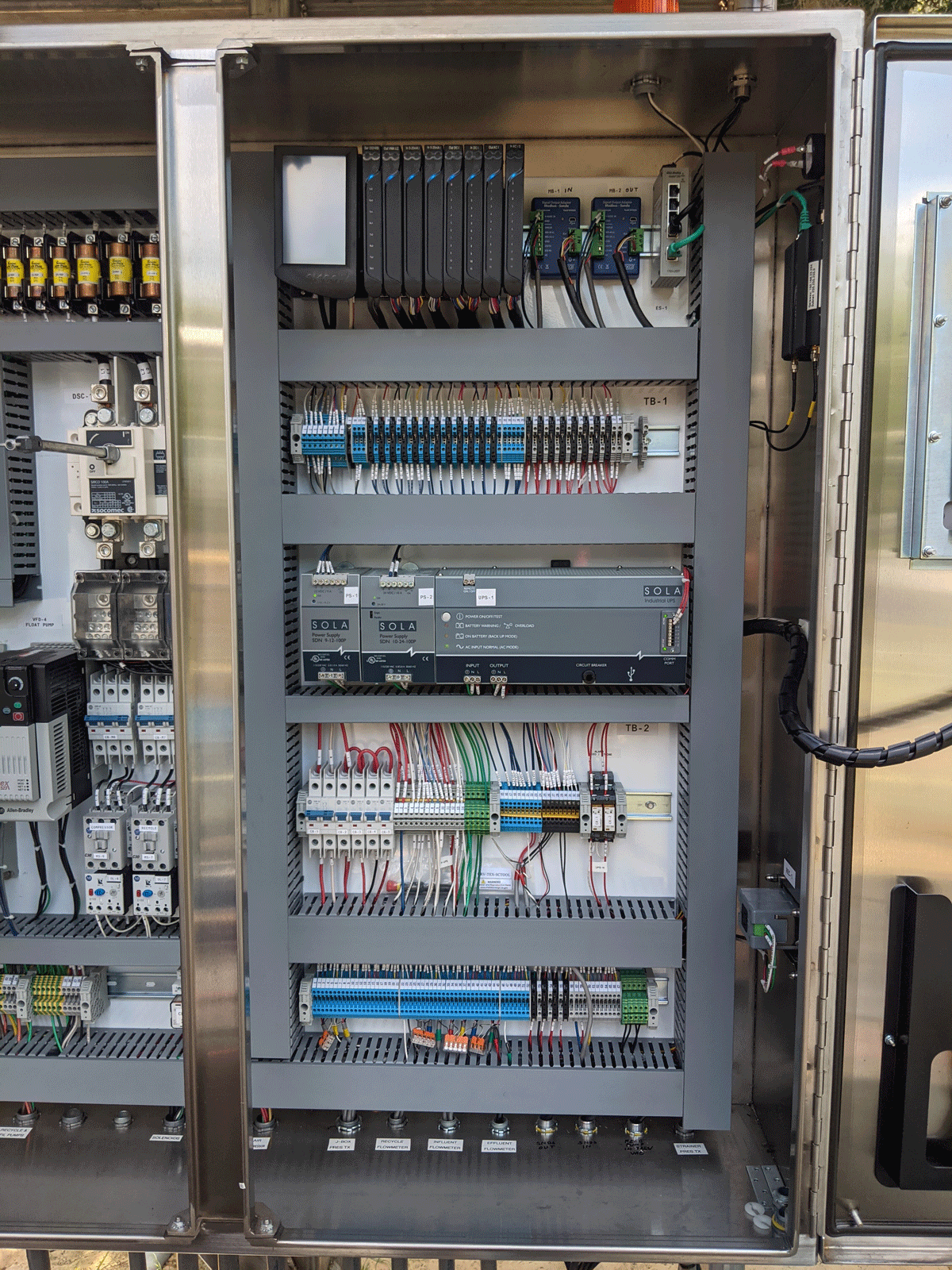

The groov EPIC System (center top) provides real-time control, connectivity to all parts of the process, data storage and communication, and the operator interface.

The harvester’s groov EPIC system consists of an industrial Linux®-based edge programmable industrial controller, power supply, and the following I/O modules, all mounted on a single chassis:

● One 12-channel AC discrete input module

● One 12-channel DC discrete input module

● Three 8-channel AC/DC electromechanical relay output modules

● One 24-channel analog input module

● One 8-channel analog output module with chassis-powered loop

● One 4-channel serial communication module

The system also includes a cellular router for remote access and for automated reporting via email. Because the EPIC system was designed to handle data communication from the edge of a network to the cloud, it offers built-in security features and connectivity options in addition to controlling the process and communicating with other elements of the overall system.

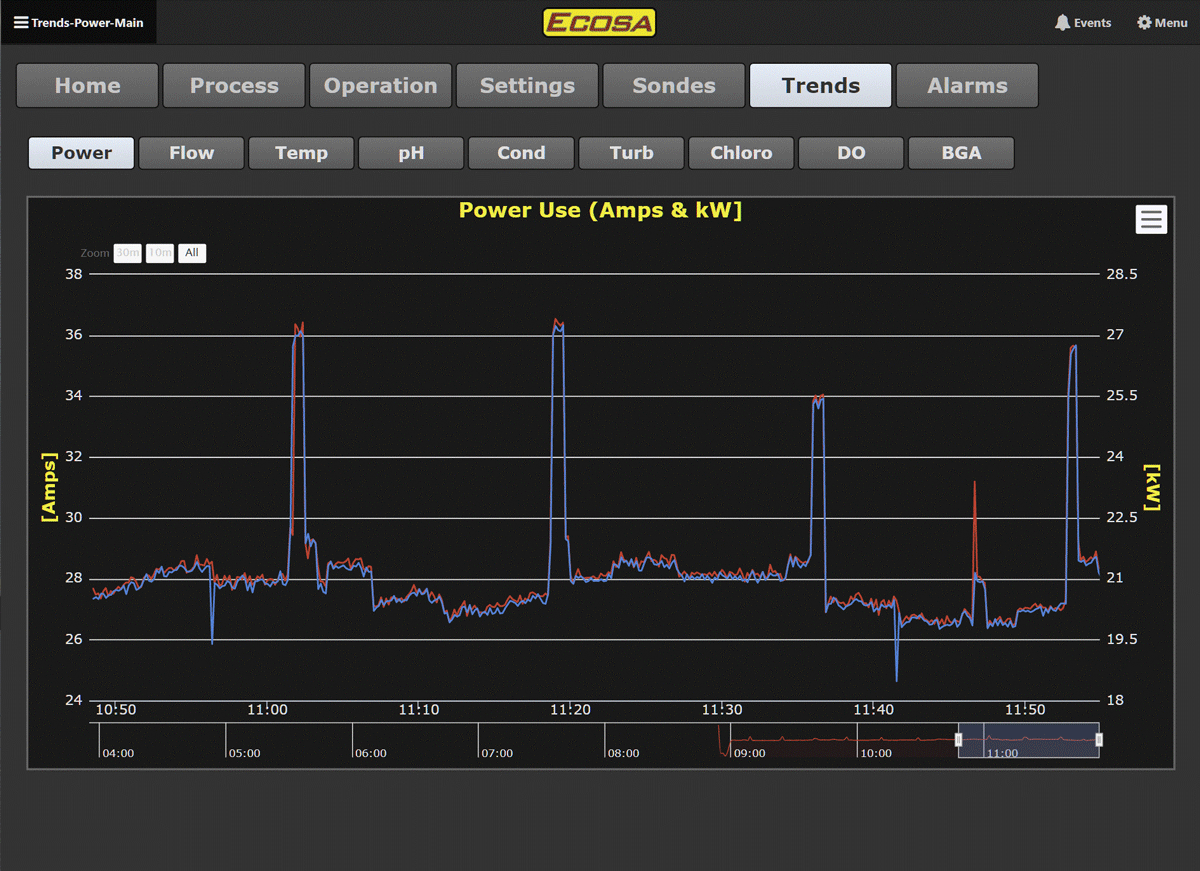

Guy uses one of the USB ports on the EPIC processor for removable data storage. When the program detects end-of-day, whether at midnight or during an orderly shutdown, data summaries are automatically emailed for off-site storage and reporting, and a new daily file is started. Data reports include operational parameters, power usage, system status details, and an extensive set of analytical data collected via influent and effluent water quality sondes (sounding devices containing sensors) attached to the harvester. The program also detects end-of-month events and starts a new monthly file at that point. Both daily data and cumulative monthly data are stored locally and emailed daily, with a daily summary in the body of the email.

Modbus communication is used for communication to the multi-parameter sondes. Separate influent and effluent sondes each include multiple probes that monitor water quality and system performance, including temperature, pH, turbidity, chlorophyll levels, dissolved oxygen, and more. The sondes communicate via a Modbus adapter directly to the serial module on the EPIC. The EPIC’s programming controls the sensors’ reading, cleaning, and recording cycle.

Guy reached out to Dave Engsberg with Tellus, a long time colleague and an Opto 22 expert, for help in developing Modbus communication, data handling, and emailing charts and subroutines.

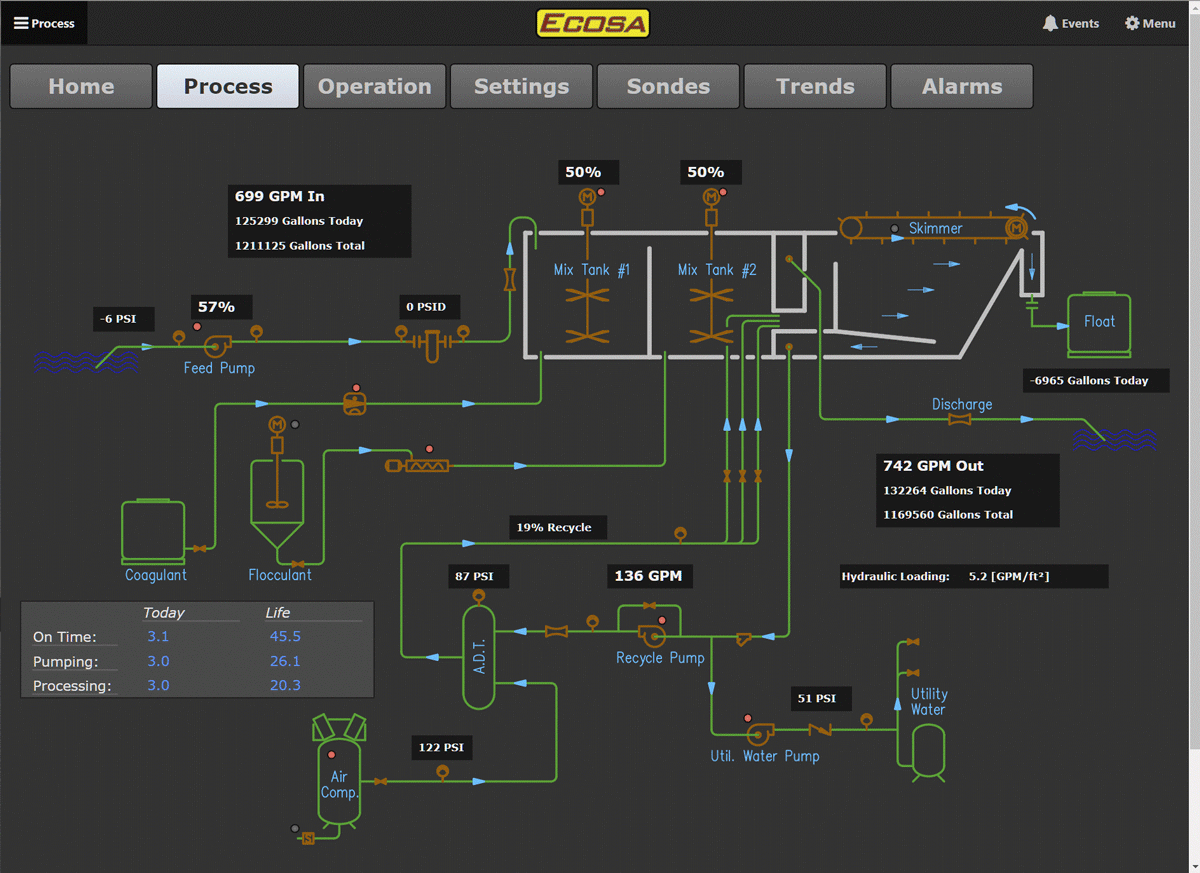

The HMI Guy built using the EPIC’s included groov View® software is “permission-driven,” he explains, “so an operator sees different screens than someone reviewing data and operations.” The HMI consists of several screens. Operator screens are for setting and operating pumps, pressures, tanks, agitator, and the skimmer, which can run continuously or intermittently. Other screens show alarms, power usage, processing, data from the process and sondes, and trends over time.

The HMI is accessed via a panel-mount touchscreen connected to the HDMI port on the EPIC. The HMI can also be accessed remotely through the cellular router. In groov View, Guy adapted all HMI screens to a fully functioning mobile device interface so that operators can use it in Opto 22’s groov View app. (The screenshots that follow show the touchscreen view, not the mobile view.)

Guy Chetrit built the operator interface using groov View, HMI software included with the groov EPIC. The HMI can be viewed locally and by authorized users on PCs or mobile devices anywhere in the world.

“This equipment is totally accessible for me coming as a mechanical engineer,” says Guy. “I can build a system without being a system integrator. I’ve used Opto 22 hardware on many projects in the past 20 years. The components are made in the U.S. and their exceptional technical support is in the U.S. Most of the components have a lifetime warranty and the cost is appealing. It’s a no-brainer to use Opto.”

AECOM technicians operate each system, and the VPN client on the groov EPIC processor makes it possible to securely access the EPIC from just about anywhere.

“They love the remote access, and so do I,” Guy says. From his office in Minnesota, he can log in at any time to any unit in the field, just to check on it or to update its control program or HMI.

Guy has found this project rewarding. “It’s nice to solve a problem that hasn’t been solved in this way before. And have the liberty to do it high class—with all stainless steel construction and an elaborate control system.”

The Result

Today, the team has developed a comprehensive restoration program that can be scaled to any size and used throughout the U.S.—and the world. The technical process has proven to be safe, highly effective, and efficient, achieving algae removal percentages in the high 90s. And unlike other methods, it removes nutrients as well as algae, so blooms are less likely to recur.

The algae biomass solids offer many opportunities for beneficial use to promote sustainability and help decarbonize our planet. The team is actively exploring several promising uses, including conversion to biocrude oil, biofertilizer, biofoam, and bioink. In all forms of reuse, toxins are destroyed in the transformation process.

To provide a closed-loop system with virtually no waste, AECOM has been working with industry leaders to transform the recovered algae into clean, carbon-neutral energy. Last summer in Ohio, AECOM conducted the first ever field-scale algae-to-fuel demonstration project. A 1-MGD harvester was used to remove algae from Harsha Lake, a drinking water source and recreational water body outside of Cincinnati.